How to Choose the Best Boxes for Packaging Your Products Effectively

When it comes to ensuring the safety and appeal of your products during transportation, choosing the right boxes for packaging is paramount. Expert in packaging solutions, Rebecca Larson, emphasizes, “Selecting the appropriate boxes for packaging not only protects your product but also enhances your brand’s image.” With the rapidly evolving marketplace, businesses must prioritize packaging as it serves as the first point of interaction between the consumer and the brand.

The choice of packaging boxes can influence both customer satisfaction and operational efficiency. From understanding materials and dimensions to considering aesthetics and functionality, the process can be complex. It’s essential to strike the right balance to ensure that your products are not only securely packaged but also visually appealing. As we explore the various factors influencing the selection of boxes for packaging, it becomes clear that making an informed decision is crucial for any successful business strategy.

How to Identify the Right Box Type for Your Product's Protection Needs

Choosing the right box for packaging your products is crucial not only for protection but also for enhancing the customer experience. According to a recent report by the Freedonia Group, the demand for rigid boxes is expected to grow by 3.9% annually through 2025, driven largely by their ability to offer enhanced durability. Selecting a box that matches the weight, shape, and fragility of your product can greatly reduce damage during transit. For instance, heavier items necessitate sturdier materials, such as corrugated cardboard, which provides additional strength and protection compared to regular paperboard.

When assessing your product’s protection needs, consider factors such as environmental conditions it may encounter during shipping. The Packaging Institute suggests that nearly 30% of products are damaged during transit, often attributed to inadequate packaging solutions. Specialized packaging options, like foam inserts or molded pulp, can mitigate this risk, ensuring that your products remain secure. Conducting a risk assessment can guide you to select packaging that not only withstands physical stress but also protects against moisture and temperature variations, enhancing your overall product integrity during its journey to the customer.

Product Packaging Box Types and Their Protection Levels

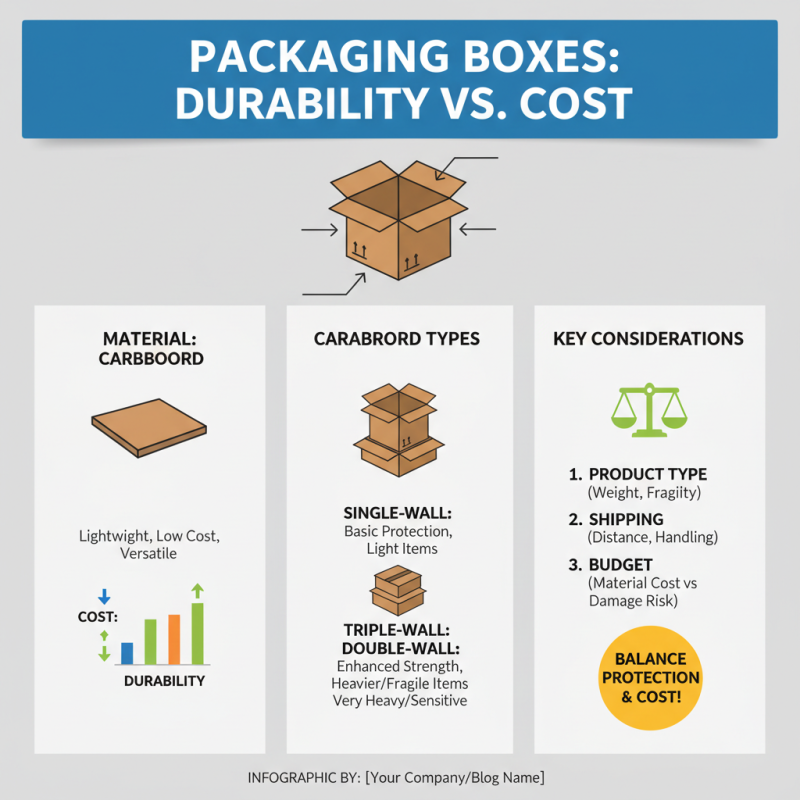

Evaluating the Impact of Box Materials on Packaging Durability and Cost

When selecting boxes for packaging products, understanding the impact of different box materials on durability and cost is essential. Cardboard, for instance, is widely used due to its lightweight nature and relatively low cost, making it an ideal choice for many businesses. Single-wall cardboard offers basic protection, while double-wall and triple-wall options provide enhanced strength, suitable for heavier or fragile items. However, the choice of cardboard thickness directly affects cost, so businesses must balance their need for protection with budget considerations.

Additionally, materials like corrugated plastic and metal can offer superior durability in certain scenarios. Corrugated plastic boxes are water-resistant and can withstand rough handling, making them suitable for shipping in diverse environments. However, they often come at a higher price point. Metal boxes, known for their robustness and longevity, can significantly increase initial costs but may be more cost-effective in the long run for products that require repeated shipments. By evaluating product vulnerability alongside material properties, companies can identify the most effective packaging solutions that optimize both durability and cost-efficiency.

Understanding the Role of Box Dimensions in Shipping Efficiency and Cost

When it comes to packaging products, the dimensions of the boxes you choose play a crucial role in optimizing shipping efficiency and controlling costs. According to a report by the International Journal of Logistics Management, the right box dimensions can enhance space utilization, reducing both dimensional weight and the overall shipping costs. This is particularly important in the age of e-commerce, where shipping expenses are a significant part of overhead. A study found that optimizing box dimensions can lead to savings of up to 30% in shipping costs for businesses, especially if they are frequently sending products of varying sizes.

Additionally, the selection of box dimensions influences how well products are protected during transit. Research from the Packaging Engineering Society indicates that properly sized boxes not only minimize movement during shipping but also reduce the risk of damage, which can lead to costly returns and unhappy customers. A box that fits the product snugly can lessen the need for internal cushioning materials, further driving down packaging costs. By prioritizing box dimensions, companies can efficiently manage both logistics and customer satisfaction, creating a more streamlined supply chain that benefits both the business and its customers.

How to Choose the Best Boxes for Packaging Your Products Effectively

| Box Type | Dimensions (L x W x H in inches) | Weight Capacity (lbs) | Shipping Cost (per box) | Best for |

|---|---|---|---|---|

| Regular Slotted Container | 12 x 12 x 12 | 30 | $2.00 | Small Electronics |

| Die-Cut Box | 10 x 10 x 5 | 20 | $1.50 | Retail Products |

| Flat Box | 16 x 10 x 2 | 15 | $1.00 | Books & Documents |

| Heavy Duty Box | 20 x 20 x 20 | 60 | $3.50 | Tools & Appliances |

| Padded Mailer | 9 x 12 | 2 | $0.75 | Jewelry & Small Items |

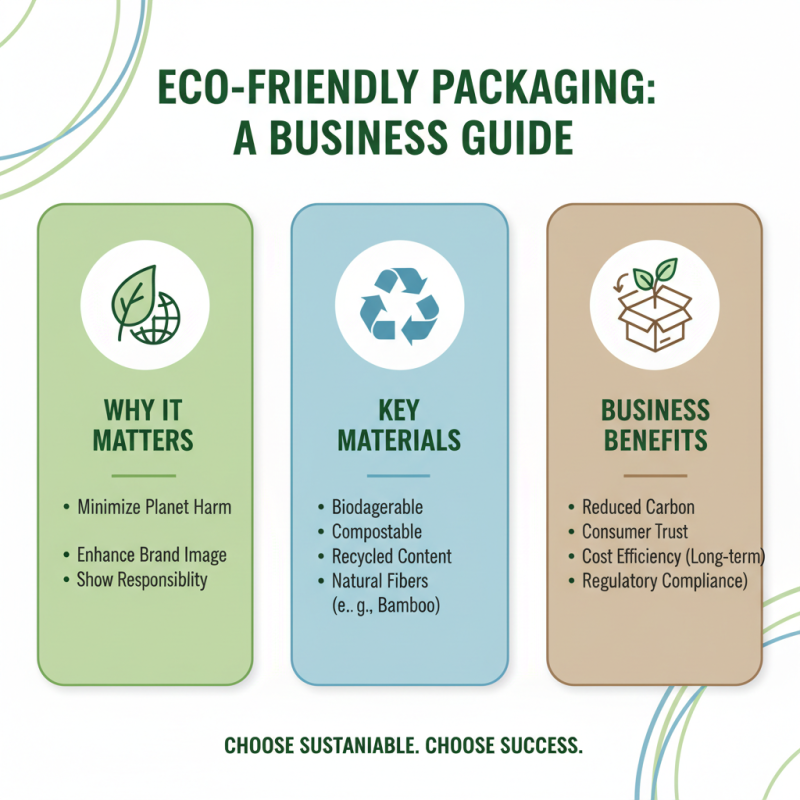

Assessing Environmental Impact: Choosing Eco-Friendly Packaging Solutions

When selecting packaging solutions, assessing the environmental impact is crucial for businesses aiming to adopt sustainable practices. Eco-friendly packaging minimizes harm to the planet and provides an opportunity for companies to enhance their brand image by demonstrating environmental responsibility. One of the first steps in choosing eco-friendly packaging is to consider the materials involved. Options such as biodegradable, compostable, or recycled materials significantly reduce the ecological footprint compared to traditional plastics or styrofoam.

In addition to material selection, companies should think about the lifecycle of their packaging. This involves evaluating how packaging is produced, transported, used, and disposed of. Efficient design can lead to less waste and lower emissions. For instance, lightweight packaging reduces shipping costs and carbon footprints while still ensuring product safety. Furthermore, engaging in practices like using minimalistic designs can also contribute to sustainability by reducing the amount of material needed. By prioritizing these eco-conscious strategies, businesses can contribute positively to the environment while meeting consumer demand for responsible packaging solutions.

Leveraging Industry Trends: Custom Packaging Design for Brand Differentiation

In today's competitive market, custom packaging design has emerged as a pivotal strategy for brands seeking differentiation. According to a report by Smithers Pira, the global market for packaging is expected to reach $500 billion by 2024, with an increasing emphasis on sustainability and consumer engagement. Brands that leverage unique packaging designs can reinforce their identity, foster customer loyalty, and create memorable unboxing experiences. For instance, 72% of consumers believe that packaging design influences their purchasing decisions, highlighting the importance of investing in custom packaging that resonates with target audiences.

Moreover, embracing current industry trends can significantly enhance a brand’s visibility. A survey conducted by Packaging Strategies indicates that 64% of consumers are willing to pay more for products that come in attractive, well-designed packaging. This shift indicates a clear market demand for innovation in packaging design. Brands that utilize eco-friendly materials, interactive designs, or statement graphics not only meet consumer preferences but also contribute to a positive brand perception. By keeping abreast of these trends and focusing on a tailored packaging approach, companies can effectively set themselves apart in a saturated market.

Related Posts

-

How to Choose the Best Boxes for Packaging Your Products Effectively

-

Top 10 Essential Packaging Supplies Every Business Should Consider

-

How to Choose the Best Paperboard Packaging for Your Products

-

Top 5 Film Packaging Solutions You Need to Know for Your Business

-

Ultimate Guide to Corrugated Box Tips for Effective Packing and Shipping

-

Top 5 Innovative Carton Packaging Solutions for Sustainable Business Growth